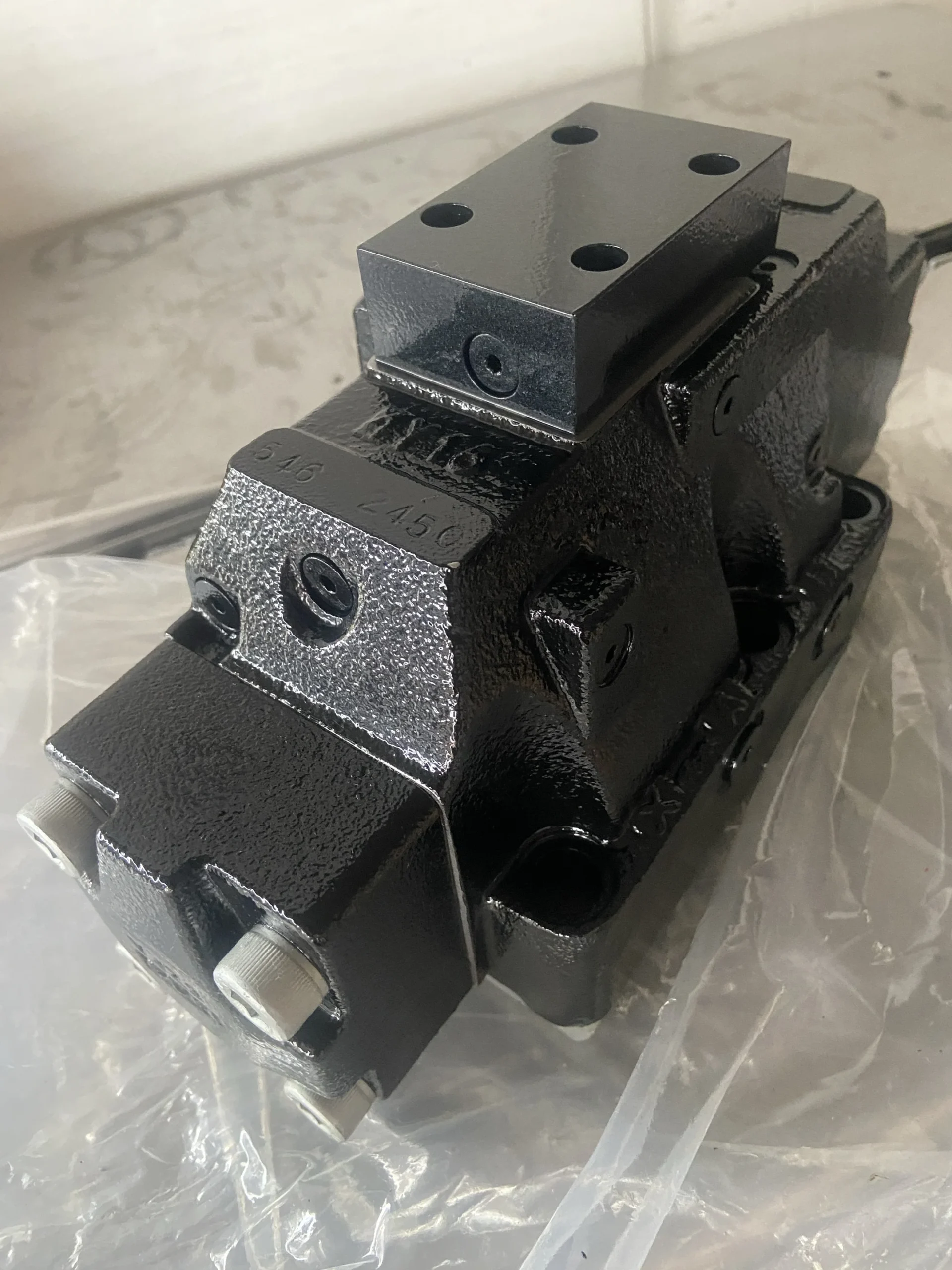

DG3V DG5V DG4V DG5S DG3V-8-2C-10 Hydraulic Solenoid Directional Control Valve DG5V-8-H-2C-T-M-U-D-10

| Model Number | DG3V-8-2C-10 |

|---|

Product Description

DG3V DG5V DG4V DG5S Hydraulic Solenoid Valve DG3V-8-2C-10 Hydraulic Solenoid Directional Control Valve DG5V-8-H-2C-T-M-U-D-10

Maximum flow rate: 700 L/min (185 USgpm

Maximum working pressure: 350 bar (5000 psi)

Valve port connection: ISO 4401-08 (CETOP 8S) standard plate mounting

Weight: Approximately 7.3 kg (16.1 lb) (excluding the electromagnet)

Valve core type: 2C type (spring pair medium-sized), three-position four-way

Pilot pressure range: Internal pilot ≥20 bar, external pilot ≥5 bar

Response time

Power-on: ≤75 ms (AC), ≤90 ms (DC)

Power-off: ≤40 ms (AC), ≤45 ms (DC)

Voltage specification

Dc: 12V, 24V, 48V, 110V, 220V

Ac: 24V, 110V, 220V, 380V (50/60Hz)

Power consumption

Ac: 37W (110V/60Hz), 154W (230V/60Hz)

Dc: Approximately 30W

Protection grade: IP65 (Dust and water resistant)

Ambient temperature: -20℃ to +65℃Ii. Working Principle

DG3V-8-2C-10 is a pilot-operated three-position four-way electromagnetic directional control valve, featuring a two-stage control structure:

Pilot stage: Composed of an electromagnetic coil, a pilot valve core and a reset spring

When the coil is energized → a magnetic field is generated → the iron core is attracted → the pilot valve core is pushed to move

When power is cut off, the spring pushes the pilot valve core back to the center position

Main stage: Composed of the main valve core, reset spring and pilot piston

The pilot valve core moves → changes the pressure distribution at the pilot oil port → drives the main valve core to act

The position of the main valve core determines the connection status of the P, A, B and T oil ports

Valve core function (2C type) :

Power failure (median) : Port P is closed, while ports A and B are connected to port T

When an electromagnet A is energized: P→A, B→T

When the B electromagnet is energized: P→B, A→T

Iii. Product Features and Advantages

High pressure and large flow rate: It can operate under a pressure of 350 bar and has a flow rate of up to 700 L/min, making it suitable for high-pressure and heavy-load systems

Low impact feature: The valve core design is optimized to reduce reversing impact and extend the system’s lifespan

Compact design: Compact structure, small space occupation, and convenient for equipment integration

Multiple control options

Internal/external leading pressure

Internal/external pilot oil drain

Stroke limit and hydraulic damping (optional)

High reliability

The wet electromagnet design ensures good heat dissipation and a long service life

The valve core is wear-resistant treated and suitable for frequent operation

It has strong anti-pollution ability and can adapt to harsh working conditions

Easy to maintain

Modular design, easy to disassemble and replace

It can be maintained without special tools

Iv. Usage Functions and Purposes

Directional control: Alter the flow direction of the hydraulic oil to control the movement direction of the actuating elements (cylinders, motors)

Flow distribution: Distribute hydraulic oil to different actuating components to achieve complex action coordination

System unloading: In the neutral position, the output oil of the pump can be directly returned to the oil tank, reducing energy consumption

Safety protection: It can be used in conjunction with other valve types to achieve safety functions such as overload protection and sequential action

V. Applicable Machines and Scenarios

Typical equipment in application fields

Construction machinery: excavators, loaders, cranes, rollers, concrete pump trucks

Metallurgical equipment: steel rolling mills, continuous casting equipment, blast furnace charging systems

Mining machinery: shield machines, mine hoists, crushers

Control of the template movement and ejection mechanism of injection molding machines

Marine machinery, deck machinery, steering gear systems, anchor winches

Industrial automation machine tool worktable movement, fixture control, production line equipment

Hydraulic suspension systems for agricultural machinery tractors and combine harvesters

Particularly suitable for: Heavy-duty hydraulic systems that require precise directional control and large flow rates

Six. Similar models

The main differences of the model and the applicable scenarios

DG3V-8-*A spring offset type (single electromagnet), returns to the A position when power is off, suitable for simple systems that only require unidirectional control

DG3V-8-*B spring offset type (single electromagnet), when power is off, return to the B position as above, but in the opposite direction

The DG3V-8-*C spring pair is medium-sized (with double electromagnets). It returns to the middle position after power failure and is suitable for systems that require precise position control and safe positioning after power failure

The DG3V-8-*D pressure is suitable for medium-sized systems that rely on pilot pressure to maintain the median position, saving spring space for systems with limited space

DG5V-8-*C features a larger flow rate (700 L/min), higher pressure (350 bar), and a more robust structure, making it an ideal choice for heavy-duty construction machinery and metallurgical equipment

The DG3V-5-*C has a smaller diameter and a flow rate of approximately 160 L/min, making it suitable for small and medium-sized equipment and auxiliary oil circuits in medium and small flow systems

Vii. Precautions for Use

1. Installation requirements

Clean the pipeline: Thoroughly clean and blow the pipeline before installation to prevent impurities from entering the valve and causing it to get stuck

Correct positioning: Install as indicated by the arrow on the nameplate and ensure the oil port is connected correctly

Firmly fixed: Use the specified torque to tighten the installation bolts to prevent loosening due to vibration

Electrical connection

Ensure that the voltage is consistent with the coil specification (within ±10% range)

Good grounding prevents electric leakage accidents

2. Usage Precautions

System pressure: Not exceeding the rated pressure of 350 bar, and the instantaneous peak pressure does not exceed 420 bar

Oil temperature control: Ensure that the system oil temperature is within the range of -20 ℃ to +65℃ to prevent seal aging caused by high temperature

Flow matching: The system flow should not exceed 700 L/min; otherwise, it will affect the control accuracy

Leading pressure

Internal pilot type: The P port must be equipped with a check valve to maintain a pilot pressure of ≥20 bar

External pilot type: The pilot pressure must be ≥5 bar

Back pressure limit: The back pressure at port T shall not exceed 50 bar; otherwise, it will affect the reset of the valve

3. Maintenance and care

Regular inspection

Check if the connection parts are loose

Is the coil overheated?

Is there any leakage?

Cleaning and maintenance

Check the filter element every 500 hours and replace it if necessary

Regularly clean the surface of the valve body to prevent oil accumulation

Long-term disuse

The valve should be placed in the middle position

Cut off the power supply

Add anti-rust oil when necessary

4. Troubleshooting

Valve core jamming

Reasons: Oil contamination, excessively high oil temperature, improper installation

Solution: Clean the system, replace the filter element, and check the installation

Leakage

Reason: Aging of the sealing ring and wear of the valve core

Solution: Replace the sealing parts and inspect the valve core

Slow response

Reasons: Insufficient pilot pressure, high oil viscosity, low coil voltage

Solution: Inspect the pilot system, replace the oil with the appropriate viscosity, and ensure the voltage is normal

Company Profile

Frequently Asked Questions

1.What ls our Main Products?

1.Hydraulic pump

2.Hydraulic valve

3.Hydraulic motor

4.Hydraulic cylinder

5.Hydraulic parts

2. What about the MOQ?

3.What are your advantages?

- Adhere to quality first.

- Support customization, ODM & OEM service.

- 1-year warranty and complete after-sales support.

- Safe and fast shipping worldwide.

- 24-hour online service for your inquiries.

4.Are you a manufacturer? What’s your delivery time?

5.Which payment methods are accepted?

6.How will you deliver my goods?

7.How do you inspect and guarantee your products?

8.What about after-sales service?

9.What are your main applications?

- Hydraulic systems

- Agricultural machinery

- Construction machinery

- Automobile industry

- Local distributors and maintenance centers

10.Can I get a discount for bulk orders?

Professional Manufacturer