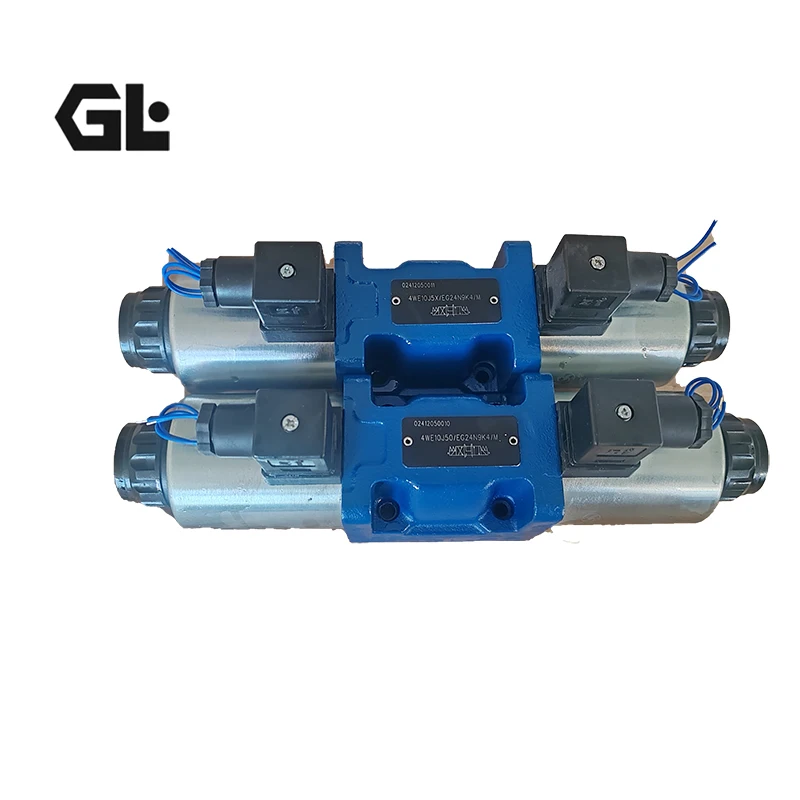

4WE 6 D6X/EG24N9K4 R900561274 R900924874 4WEH16D72/6EG24N9ETK4/B10 Hydraulic Solenoid Directional Valve

| Model Number | 4WE 6 D6X/EG24N9K4, 4WEH16D72/6EG24N9ETK4/B10 |

|---|

SKU

N/A

Categories Hydraulic Valve, Pressure Valve

Tags 12v hydraulic valve, air valve, cross hydraulic valve, danfoss hydraulic valves, gas valve, hydraulic control valve, hydraulic directional control valves, hydraulic dump valve, hydraulic flow control valve, hydraulic solenoid valve, ksb valve, lpg valve, mac valve, rexroth hydraulic valve, valve

Product Description

4WE 6 D6X/EG24N9K4 R900561274 ZHENYUAN R900924874 4WEH16D72/6EG24N9ETK4/B10 Hydraulic Solenoid Directional Valve

Features

▶ 4/3, 4/2 or 3/2 directional design

▶ High-power solenoid

▶ Porting pattern according to DIN 24340 form A

▶ Porting pattern according to ISO 4401-03-02-0-05 and NFPA T3.5.1 R2-2002 D03

▶ Wet-pin DC or AC solenoids with detachable coil

▶ Solenoid coil can be rotated by 90°

▶ The coil can be changed without having to open the pressure-tight chamber

▶ Electrical connection as individual or central connection

▶ Manual override, optional

▶ Spool position monitoring, optional

The 4WE 6D6X /EG24N9K4 is a direct-acting electromagnetic directional control valve, often used in hydraulic systems to control the flow direction of oil, thereby achieving the action switching of the actuator. The following is a detailed explanation from multiple aspects and lists the complete models of this series:

Model Analysis

4WE: Series code, representing direct-acting electromagnetic directional control valve, belongs to the major category of hydraulic directional control valves

6: Diameter specification, indicating that the diameter of this valve is 6mm, determines the basic flow capacity of the valve

D: The median function code of the valve core corresponds to a specific median oil flow channel design, determining the connection status of each oil port when the valve core is in the middle position, and adapting to the pressure holding and pressure relief requirements of different hydraulic circuits

6X: Series version identifier, representing the 60-69 series. Under this series, the installation dimensions and oil port specifications remain consistent, facilitating replacement and adaptation among different sub-models

E: The type code for electromagnets, referring to high-power wet electromagnets, which feature good heat dissipation, stable operation, and detachable coils

G24: Power supply parameters, where G stands for DC voltage and 24 is compatible with a 24V DC power supply, providing driving power for the electromagnet

N9: Manual operation marking, indicating that it is equipped with an implicit manual emergency operation function, which can manually control the valve core’s movement in special working conditions such as power failure

K4: Electrical wiring form code, indicating the individual wiring method, with a plug positioning pin that complies with DIN43650-AM2 standard, and a wire-free socket

Core attribute

The type is a direct-acting electromagnetic directional control valve, and the material is mostly cast iron, ensuring structural strength and resistance to hydraulic oil corrosion.

The maximum working pressure can reach up to 350bar, meeting the pressure requirements of common industrial hydraulic systems and being compatible with mainstream media such as petroleum-based hydraulic oil.

The installation surface complies with DIN24340A type and ISO4401 standards, and is compatible with standard installation base plates. The electrical interfaces follow general wiring specifications.

The nominal flow rate is suitable for a 6mm diameter specification. Generally, the flow range can meet the action requirements of medium and small power hydraulic actuators.

Function and Role

Core function: Control the axial movement of the valve core by turning the electromagnet on and off, switch the oil passage connection mode between the valve core and the valve body, and achieve precise switching of the oil flow direction. At the same time, with the design of the median function D type, it meets the specific pressure control requirements of the circuit and has a manual emergency operation function to deal with sudden power outages.

Main function: As the “command execution element” of the hydraulic system, it controls the start, stop, reversing and stopping actions of hydraulic cylinders, hydraulic motors and other execution elements. For instance, controlling the extension and retraction of the robotic arm and its steering, as well as the advance and retreat of the machine tool’s worktable, are key components that ensure the orderly switching of the hydraulic system’s actions.

Working principle

This valve operates based on the principle of electromagnet drive and valve core reversing. When not powered on, the valve core is in the neutral position under the action of the reset spring, and at this time, the oil flow state follows the D-type neutral function. When the 24V DC power supply is connected, the electromagnet is energized to generate magnetic force, which overcomes the spring force to push the valve core to move, connecting the oil inlet and outlet on the valve body with the corresponding oil ports of the actuator. The oil flows along the preset path, driving the actuator to act. When the power is cut off, the magnetic force of the electromagnet disappears, and the reset spring pushes the valve core back to the neutral position, restoring the oil flow state to the neutral mode. In case of power failure, the valve core can be pushed through the implicit manual operating mechanism corresponding to N9 to temporarily switch the oil passage.

Installation Precautions

Before installation, the valve body installation surface and connecting pipelines should be cleaned to remove iron filings, oil stains and other impurities to prevent impurities from entering the valve core gap and causing jamming. At the same time, check whether the sealing parts are intact to prevent leakage.

When installing, it is necessary to ensure that the valve body is closely attached to the installation base plate, and the torque of the bolts is uniform to avoid deformation of the installation surface which may affect the movement of the valve core. The installation surface must comply with the corresponding DIN and ISO standards.

For electrical wiring, it is necessary to verify the voltage and wiring method to ensure that the positive and negative poles of the 24V DC power supply are correctly connected, and the wiring points are firmly fixed to prevent loosening and poor contact of the electromagnet. Moreover, the signal lines should be kept away from strong current circuits to avoid electromagnetic interference.

When connecting hydraulic pipelines, pay attention to the oil port markings to avoid reversing the inlet and return oil ports. The sealing of pipeline joints must be reliable. It is strictly prohibited to use sealing materials that are prone to fall off to prevent oil leakage.

The installation location should avoid heat sources from the system as much as possible. At the same time, reserve space for manual operation to facilitate emergency operations in case of unexpected situations.

Application scenarios and models used

Application scenarios: Widely used in hydraulic systems of machine tool processing, injection molding and die-casting, construction machinery, automated production lines, ship deck machinery, etc. It is suitable for working conditions that require frequent switching of actuator actions. It can be used not only in fixed equipment in industrial workshops but also in complex working conditions of outdoor construction machinery.

The types of machines used: Commonly found in CNC milling machines, injection molding machines, die-casting machines, excavators, loaders, hydraulic mechanical arms, hydraulic systems of ship steering gears, small cranes and other equipment that rely on hydraulic drive.

A complete list of 4WE series models

This series is rich in models, covering different diameters, mid-range functions and power supply specifications. The following are some common complete models:

4WE6D6X/EG24N9K4

4WE6D6X/EG24N9K4/B10

4WE6D62/EW230N9K4

4WE6J62/EG24N9K4

4WE6J6X/EG24N9K4/V

4WE6E6X/EG24N9K4

4WE6C7X/HG24N9K4

4WE6H6X/EG24N9K4

4WE6FA6X/EG24N9K4

4WE10D3X/OFCG24N9K4/V

4WE10J3X/CG24N9K4

4WE10G33/CG24N9K4

4WE10J733X/CG24N9K4/A12/V

4WEH16J7X/6EG24N9ES2K4

4WEH25J6X/6EG24N9ES2K4B10D3

Model Analysis

4WE: Series code, representing direct-acting electromagnetic directional control valve, belongs to the major category of hydraulic directional control valves

6: Diameter specification, indicating that the diameter of this valve is 6mm, determines the basic flow capacity of the valve

D: The median function code of the valve core corresponds to a specific median oil flow channel design, determining the connection status of each oil port when the valve core is in the middle position, and adapting to the pressure holding and pressure relief requirements of different hydraulic circuits

6X: Series version identifier, representing the 60-69 series. Under this series, the installation dimensions and oil port specifications remain consistent, facilitating replacement and adaptation among different sub-models

E: The type code for electromagnets, referring to high-power wet electromagnets, which feature good heat dissipation, stable operation, and detachable coils

G24: Power supply parameters, where G stands for DC voltage and 24 is compatible with a 24V DC power supply, providing driving power for the electromagnet

N9: Manual operation marking, indicating that it is equipped with an implicit manual emergency operation function, which can manually control the valve core’s movement in special working conditions such as power failure

K4: Electrical wiring form code, indicating the individual wiring method, with a plug positioning pin that complies with DIN43650-AM2 standard, and a wire-free socket

Core attribute

The type is a direct-acting electromagnetic directional control valve, and the material is mostly cast iron, ensuring structural strength and resistance to hydraulic oil corrosion.

The maximum working pressure can reach up to 350bar, meeting the pressure requirements of common industrial hydraulic systems and being compatible with mainstream media such as petroleum-based hydraulic oil.

The installation surface complies with DIN24340A type and ISO4401 standards, and is compatible with standard installation base plates. The electrical interfaces follow general wiring specifications.

The nominal flow rate is suitable for a 6mm diameter specification. Generally, the flow range can meet the action requirements of medium and small power hydraulic actuators.

Function and Role

Core function: Control the axial movement of the valve core by turning the electromagnet on and off, switch the oil passage connection mode between the valve core and the valve body, and achieve precise switching of the oil flow direction. At the same time, with the design of the median function D type, it meets the specific pressure control requirements of the circuit and has a manual emergency operation function to deal with sudden power outages.

Main function: As the “command execution element” of the hydraulic system, it controls the start, stop, reversing and stopping actions of hydraulic cylinders, hydraulic motors and other execution elements. For instance, controlling the extension and retraction of the robotic arm and its steering, as well as the advance and retreat of the machine tool’s worktable, are key components that ensure the orderly switching of the hydraulic system’s actions.

Working principle

This valve operates based on the principle of electromagnet drive and valve core reversing. When not powered on, the valve core is in the neutral position under the action of the reset spring, and at this time, the oil flow state follows the D-type neutral function. When the 24V DC power supply is connected, the electromagnet is energized to generate magnetic force, which overcomes the spring force to push the valve core to move, connecting the oil inlet and outlet on the valve body with the corresponding oil ports of the actuator. The oil flows along the preset path, driving the actuator to act. When the power is cut off, the magnetic force of the electromagnet disappears, and the reset spring pushes the valve core back to the neutral position, restoring the oil flow state to the neutral mode. In case of power failure, the valve core can be pushed through the implicit manual operating mechanism corresponding to N9 to temporarily switch the oil passage.

Installation Precautions

Before installation, the valve body installation surface and connecting pipelines should be cleaned to remove iron filings, oil stains and other impurities to prevent impurities from entering the valve core gap and causing jamming. At the same time, check whether the sealing parts are intact to prevent leakage.

When installing, it is necessary to ensure that the valve body is closely attached to the installation base plate, and the torque of the bolts is uniform to avoid deformation of the installation surface which may affect the movement of the valve core. The installation surface must comply with the corresponding DIN and ISO standards.

For electrical wiring, it is necessary to verify the voltage and wiring method to ensure that the positive and negative poles of the 24V DC power supply are correctly connected, and the wiring points are firmly fixed to prevent loosening and poor contact of the electromagnet. Moreover, the signal lines should be kept away from strong current circuits to avoid electromagnetic interference.

When connecting hydraulic pipelines, pay attention to the oil port markings to avoid reversing the inlet and return oil ports. The sealing of pipeline joints must be reliable. It is strictly prohibited to use sealing materials that are prone to fall off to prevent oil leakage.

The installation location should avoid heat sources from the system as much as possible. At the same time, reserve space for manual operation to facilitate emergency operations in case of unexpected situations.

Application scenarios and models used

Application scenarios: Widely used in hydraulic systems of machine tool processing, injection molding and die-casting, construction machinery, automated production lines, ship deck machinery, etc. It is suitable for working conditions that require frequent switching of actuator actions. It can be used not only in fixed equipment in industrial workshops but also in complex working conditions of outdoor construction machinery.

The types of machines used: Commonly found in CNC milling machines, injection molding machines, die-casting machines, excavators, loaders, hydraulic mechanical arms, hydraulic systems of ship steering gears, small cranes and other equipment that rely on hydraulic drive.

A complete list of 4WE series models

This series is rich in models, covering different diameters, mid-range functions and power supply specifications. The following are some common complete models:

4WE6D6X/EG24N9K4

4WE6D6X/EG24N9K4/B10

4WE6D62/EW230N9K4

4WE6J62/EG24N9K4

4WE6J6X/EG24N9K4/V

4WE6E6X/EG24N9K4

4WE6C7X/HG24N9K4

4WE6H6X/EG24N9K4

4WE6FA6X/EG24N9K4

4WE10D3X/OFCG24N9K4/V

4WE10J3X/CG24N9K4

4WE10G33/CG24N9K4

4WE10J733X/CG24N9K4/A12/V

4WEH16J7X/6EG24N9ES2K4

4WEH25J6X/6EG24N9ES2K4B10D3

Company Profile

Frequently Asked Questions

1.What ls our Main Products?

1.Hydraulic pump

2.Hydraulic valve

3.Hydraulic motor

4.Hydraulic cylinder

5.Hydraulic parts

2. What about the MOQ?

3.What are your advantages?

- Adhere to quality first.

- Support customization, ODM & OEM service.

- 1-year warranty and complete after-sales support.

- Safe and fast shipping worldwide.

- 24-hour online service for your inquiries.

4.Are you a manufacturer? What’s your delivery time?

Yes, we are a manufacturer with our own factory.

Common models are in stock, and orders are usually shipped within 1–3 days.

5.Which payment methods are accepted?

We accept T/T, L/C, PayPal, VISA, Western Union, Apple Pay, Google Pay, Afterpay (Clearpay), Klarna, and Trade Assurance.

For full orders: 30% deposit, balance before shipment.

For small/sample orders: full payment in advance.

6.How will you deliver my goods?

We offer flexible shipping options: DHL, UPS, FedEx, TNT, EMS, as well as air or sea freight.

All deliveries ensure door-to-door fast and safe service.

7.How do you inspect and guarantee your products?

All products are tested before shipment to ensure perfect working condition.

We offer a 12-month warranty — if a product fails due to quality issues, we provide free spare parts or repair support.

8.What about after-sales service?

If you encounter any problem during use, please contact your sales manager or our support team at any time.

We will respond quickly and help solve the issue efficiently.

9.What are your main applications?

- Hydraulic systems

- Agricultural machinery

- Construction machinery

- Automobile industry

- Local distributors and maintenance centers

10.Can I get a discount for bulk orders?

Yes. We offer competitive wholesale prices and try our best to give benefits to long-term partners.

Shoot Us An Email

Professional Manufacturer