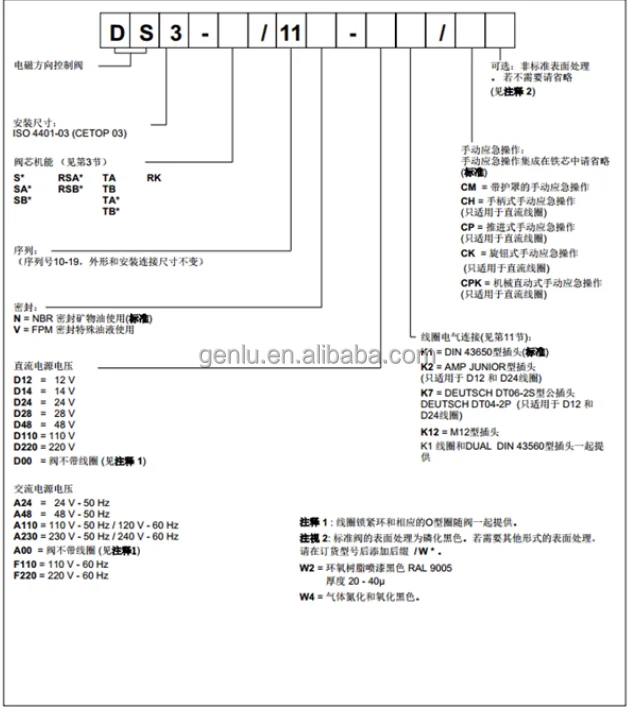

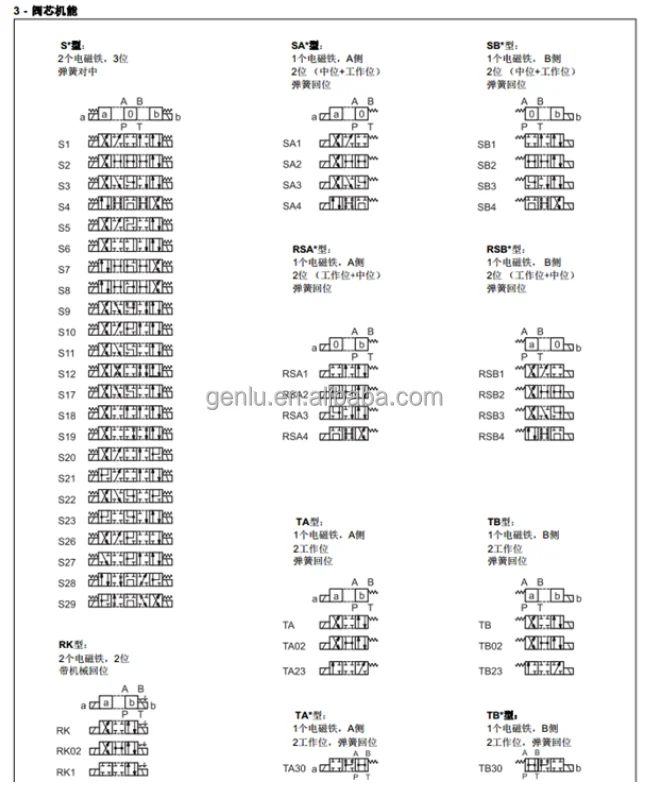

DS5-S2/12N-A230K1 DS5-S1/12N -D24K1 Electro-hydraulic Directional Valve DS3 DS5 DS DSE DSE3 DSE5

| Model Number | DS5-S2/12N-A230K1, DS5-S1/12N -D24K1 |

|---|

Product Description

DS5-S2/12N-A230K1 DS5-S1/12N -D24K1 Electro-hydraulic Directional Valve DS3 DS5 DS DSE DSE3 DSE5 Hydraulic Solenoid Valve

Core performance parameters

– Valve type: Two-position five-way single electrically controlled solenoid valve, normally open design, electromagnetic pilot control + manual emergency operation, compatible with medium and low pressure pneumatic systems, achieving bidirectional action switching of the actuator (cylinder).- Pressure and flow parameters: Rated working pressure 0.1-1.0 MPa, maximum allowable pressure 1.2 MPa; Rated flow capacity: 1200 L/min (under standard operating conditions); Control voltage: DC24V (rated current: 1.8A), pull-in power: ≤43.2W.

– Response and life parameters: The power-on engagement response time is ≤15 ms, and the power-off reset response time is ≤10 ms. The working life of the electromagnetic coil is no less than 1 million times, and the reciprocating cycle life of the valve core is no less than 5 million times. The ambient temperature adaptation range is from -20℃ to 60℃.

2. Structure and connection parameters

– Structural type: Slide valve type two-position five-way structure, composed of main valve core, electromagnetic coil, reset spring, pilot valve and manual button. It adopts pilot-operated drive, and a small power coil can drive the main valve core to act. Integrated exhaust silencing function to reduce working noise.

– Core material: The main valve core is made of engineering plastic PPS (high-temperature resistance ≤120℃); The valve body is made of aluminum alloy ADC12 (with surface anodizing treatment). The sealing part is made of oil-resistant nitrile butadiene rubber (NBR) (temperature resistance ≤80℃). The electromagnetic coil frame is made of flame-retardant nylon PA66.

– Connection specification: The interface type is threaded (P air inlet, A/B working port, and R/S exhaust port are all G1/4″). The installation method is plate mounting (compatible with the standard ISO 5599-1 mounting plate). The overall weight is approximately 0.8 kg, and the external dimensions (length × width × height) ≈160×80×100 mm.

3. Medium and Environmental requirements

– Medium requirements: Compatible with dried and filtered compressed air (dew point ≤-20℃), oil content ≤5 mg/m³, solid particle size ≤5 μm; The use of corrosive gases, dust or liquid media is strictly prohibited.

– Environmental parameters: Relative humidity of the working environment ≤90% (no condensation), protection grade IP65; It is suitable for scenarios with less dust such as industrial automated production lines, packaging equipment, and textile machinery.

Ii. Working Principle

This valve is a two-position five-way single electrically controlled solenoid valve. Its core is controlled by the pneumatic actuator through the mechanism of “electromagnetic suction force driving the pilot valve – main valve core displacement – air path on-off switching – spring return”. The specific process is as follows:

1. Constant disconnection state (when there is no electricity)

When there is no control signal, the electromagnetic coil is de-energized, and the main valve core is in the initial position under the preload force of the reset spring. At this point, the air inlet P is connected to the working port B, and compressed air enters the rodless cavity of the cylinder. The working port A is connected to the exhaust port R. The gas in the cylinder’s rod cavity is silenced through ports A and R before being discharged, and the cylinder piston rod is retracted. The exhaust port S is in a closed state, ensuring the gas passage of the constantly interrupted workstation is unobstructed.

2. Working status (when powered on

When the electromagnetic coil is energized, the coil generates an electromagnetic suction force to attract the pilot valve core, opening the pilot airway. The pilot compressed air pushes the main valve core to overcome the force of the reset spring and move to the working position, connecting the air inlet P with the working port A, and the compressed air enters the rod cavity of the cylinder. The working port B is connected to the exhaust port S. The gas in the rodless cavity of the cylinder is silenced through ports B and S and then discharged. The piston rod of the cylinder extends out. In case of emergency operation, pressing the manual button can force the main valve core to switch positions, achieving action control in the absence of electricity.

3. Reset process

After the electromagnetic coil is de-energized, the electromagnetic suction force disappears. Under the elastic force of the reset spring, the main valve core returns to its initial position, the airway returns to a normally disconnected state, and the piston rod of the cylinder retract. The residual gas in the pilot gas path is discharged through the exhaust hole of the coil to ensure that the valve core returns to its original position and avoid jamming.

Iii. Product Features and Advantages

– Quick response and precise switching: The response times for engagement and reset are ≤15 ms and ≤10 ms respectively, which is 25% faster than that of ordinary solenoid valves. The spool valve structure ensures smooth gas path switching without shock and stable cylinder operation, making it suitable for automated production lines that require rapid rhythm (such as electronic component assembly).

– Energy-saving and low-noise design: Pilot-operated drive reduces the rated current of the coil to only 1.8A, saving 30% energy compared to direct-acting solenoid valves. Integrated silencing and exhaust structure, working noise ≤65 dB (measured at 1 meter), 20 dB lower than the design without silencing, meeting the noise reduction requirements of workshops.

– High reliability and long service life: The valve core adopts an engineering plastic PPS+NBR sealing combination, which is wear-resistant and anti-aging. The cycle life of the valve core is ≥5 million times. The electromagnetic coil adopts high-temperature resistant enameled wire, with a continuous working temperature of no more than 60℃, and its service life is 50% longer than that of ordinary coils.

– Strong installation adaptability: The standardized plate installation is compatible with universal installation plates and can directly replace products of the same specification but from different brands. The G1/4″ interface is compatible with common pneumatic pipelines, and installation and commissioning only take 10 minutes. It is equipped with a manual emergency button, allowing manual operation in case of faults to enhance the system’s fault tolerance.

Iv. Usage Functions and Purposes

1. Core usage functions

– Bidirectional drive of the cylinder: Through electromagnetic control, the bidirectional action switching of the cylinder piston rod “extension – retraction” is achieved, replacing the combination of “manual valve + directional control valve”, simplifying the structure of the pneumatic system, and being suitable for scenarios such as mechanical hand grasping and conveyor belt start and stop.

– Automation control adaptation: Supports DC24V standard control signals and can be directly connected to PLC or single-chip microcomputer control systems to achieve automated cycle control (such as the “grab – package – release” cycle of packaging equipment), without the need for additional conversion modules.

– Emergency manual operation: Integrated manual button. When the electromagnetic coil malfunctions, it can forcibly switch the gas path to prevent production line shutdown. It is suitable for scenarios with high requirements for continuous operation (such as food packaging production lines).

2. Main application fields

– Industrial automation field: mechanical hand drive for automated production lines, start and stop control of conveyor conveyor belts, positioning and clamping mechanisms for assembly equipment, suitable for electronic and automotive parts assembly scenarios.

In the field of packaging machinery: Bag mouth clamping of food packaging machines, drive of label pasting mechanisms, and valve switch control of filling equipment, suitable for the food and pharmaceutical packaging industries.

In the textile and printing fields: Yarn tension control mechanisms for textile machines, paper conveying clamping drives for printing machines, and cutting blade action control for paper cutters, suitable for light-load and precise action scenarios.

V. Applicable Machines and Scenarios

1. Adapt to the core machine

– Automated equipment: small industrial manipulators, belt conveyors, electronic component assembly machines.

– Packaging machinery: Small food packaging machines, automatic labeling machines, quantitative filling equipment.

Textile printing equipment: high-speed textile machines, small gravure printing machines, fully automatic paper cutters.

2. Typical application scenarios

– Mechanical hand grasping scenario: As the drive valve of the electronic component assembly mechanical hand, it controls the cylinder to achieve the “grasping – moving – releasing” action under a pressure of 0.6 MPa, with a response time of 12 ms. Combined with the PLC, it realizes automatic grasping once per second, which is suitable for the mobile phone component assembly production line.

– Food packaging scenario: It is equipped with a small food packaging machine. The control clamping mechanism is used to position the bag opening. It clamps when powered on and releases when power is off. The manual emergency button can be forcibly released during equipment maintenance to prevent damage to the packaging film. It is suitable for biscuit and candy packaging operations.

– Conveyor belt start and stop scenario: Control the tensioning cylinder of the conveyor belt. When the sensor detects the material, the solenoid valve is energized to extend the tensioning cylinder, and the conveyor belt starts. After the material passes through, the power is cut off and reset, and the conveyor belt stops, achieving energy-saving operation and being suitable for the material sorting scenarios in the workshop.

Six. Similar models

1. Alternative models of the same series

-DS5-S1/10N-D24K1: Small bore model of the same structure, interface specification G1/8″, rated flow capacity 800 L/min, suitable for small cylinders (cylinder diameter ≤32 mm), cost 15% lower than the original model.

-DS5-S1/15N-D24K1: Large diameter models of the same series, interface specification G3/8″, rated flow capacity 1800 L/min, suitable for large cylinders (cylinder diameter ≥80 mm), cost 25% higher than the original model.

2. Cross-series alternative models

-DS5-S2/12N-D24K1: Dual electronic control model, no reset spring required. It achieves station switching through alternating energization of two coils, suitable for scenarios where the station needs to be maintained for a long time (such as continuous clamping of fixtures). The performance parameters are consistent, but the cost is 40% higher than that of the original model.

-DS5-S1/12N-AC220K1: AC control model, control voltage AC220V, suitable for scenarios without DC power supply (such as old workshops), with consistent flow and pressure parameters and the same cost.

-DS5-S1/12N-D24K1-H: High-temperature compatible model, with a working temperature range of -10℃ to 80℃. The sealing parts are made of fluororubber, suitable for high-temperature scenarios such as food baking workshops. The cost is 30% higher than that of the original model.

DS3-RK/10N-A230K1

DS3-RK/10N-D24K1 C.C.

DS3-RK/10N-D110K1 C.C.

DS3-S1/10N-A230K1

DS3-S1/10N-A110K1

DS3-S1/10N-D12K1/CM

DS3-S1/10N-D24K1

DS3-S2/10N-A230K1

DS3-S2/10N-A110K1

DS3-S2/10N-D12K1/CM

DS3-S2/10N-D24K1

DS3-S3/10N-A230K1

DS3-S3/10N-A110K1

DS3-S3/10N-D12K1/CM

DS3-S3/10N-D24K1

DS3-S4/10N-A110K1

DS3-S4/10N-D12K1/CM

DS3-S4/10N-D24K1

DS3-SA1/10N-A230K1

DS3-SA1/10N-D24K1

DS3-SA2/10N-A230K1

DS3-SA2/10N-D24K1

DS3-SA2/10N-D12K1/CM

DS3-SB1/10N-A230K1

DS3-SB1/10N-A110K1

DS3-SB7/10N-D110K1

DS3-SB7/10N-A110K1

DS3-TA/10N-A230K1

DS3-TA/10N-A110K1

DS3-TA/10N-D24K1

DS3-TB/10N-A230K1

DS3-TB/10N-D24K1

DS3-TB23/10N-A00 SENZA BOB.

DS5-RK/10N-A230K1

DS5-RK/10N-A110-50K1 DUPLOM.

DS5-RK/10N-A230-50K1 DUPLOM.

DS5-RK/10N-D24K1 DUPLOM.

DS5-RK/11N-D00 SENZA BOB.C.C

DS5-RK/11N-D00 SENZA BOB.C.C

DS5-S1/12N-A00 SENZA BOB.C.A .

DS5-S1/12N-A110-50K1 DUPLOM.

DS5-S1/12N-A230-50K1 DUPLOM.

DS5-S1/12N-A24-50K1 DUPLOM.

DS5-S1/12N-D00 SENZA BOB. CC

DS5-S1/10N-D12K1 DUPLOM.

DS5-S1/10N-D24K1 DUPLOM.

DS5-S1/11N-A00 SENZA BOB.C.A

DS5-S1/11N-A00 SENZA BOB.C.A

DS5-S1/11N-A110K1 DUPLOM.

DS5-S1/11N-D00 SENZA BOB. CC

DS5-S1/11N-D00 SENZA BOB. CC

DS5-S1/11N-D12K1 DUPLOM.

DS5-S1/11N-D24K1 DUPLOM.

DS5-S1/12N-A00 SENZA BOB.C.A.

DS5-S1/12N-A00 SENZA BOB.C.A.

DS5-S11/11N-D24K1 DUPLOM.

DS5-S11/12N-D00

DS5-S2/10N-A110-50K1 DUPLOM.

DS5-S2/10N-A230-50K1 DUPLOM.

DS5-S2/10N-D00 SENZA BOB.C.C

DS5-S2/10N-D12K1 DUPLOM.

DS5-S2/10N-D24K1 DUPLOM.

DS5-S20/12N-D12K1

DS5-S20/12N-D12K1

DS5-S3/10N-A110-50K1 DUPLOM.

DS5-S3/10N-A230-50K1 DUPLOM.

DS5-S3/10N-D00 SENZA BOB.C.C

DS5-S3/10N-D110K1 DUPLOM.

DS5-S3/10N-D110K1 DUPLOM.

DS5-S3/10N-D12K1 DUPLOM.

DS5-S3/10N-D24K1 DUPLOM.

DS5-S3/10N-D24K1/F08 DUPLOM.

DS5-S3/11N-A00-CA SENZA BOB.

DS5-S3/11N-A00-CA SENZA BOB.

DS5-S3/11N-A230K1

DS5-S3/11N-D00 SENZA BOB.C.C

DS5-S3/11N-D00 SENZA BOB.C.C

DS5-S3/11N-D12K1 DUPLOM.

DS5-S3/11N-D24K1 DUPLOM.

DS5-S3/12N-A00 SENZA BOB.C.A

DS5-S4/10N-A00 SENZA BOB.C.A

DS5-S4/10N-A110-50K1 DUPLOM.

DS5-S4/10N-A230-50K1 DUPLOM.

DS5-S4/10N-D00 SENZA BOB. CC

DS5-S4/10N-D12K1 DUPLOM.

DS5-S4/10N-D24K1 DUPLOM.

DS5-S4/11N-A00 SENZA BOB.C.A .

DS5-S4/11N-A00 SENZA BOB.C.A .

DS5-S4/12N-D00-CC SENZA BOB

DS5-S4/12N-D00-CC SENZA BOB

DS5-S6/10N-A110-50K1 DUPLOM.

DS5-S6/11N-D24K1 DUPLOM.

DS5-S6/12N-D00

DS5-S6/12N-D00

DS5-S7/10N-A110-50K1 DUPLOM.

DS5-S7/10N-A110-50K1 DUPLOM.

DS5-S7/11N-A00 SENZA BOB.C.A

DS5-S7/11N-A00 SENZA BOB.C.A

DS5-S8/10N-A00 SENZA BOB.C.A

DS5-S8/10N-A00 SENZA BOB.C.A

DS5-S9/12N-D00

DS5-S9/12N-D00

DS5-SA1/10N-A00 SENZA BOB.CA

DS5-SA1/10N-A00 SENZA BOB.CA

DS5-SA1/10N-D00 SENZA BOB CC

DS5-SA1/10N-D00 SENZA BOB CC

DS5-SA1/11N-D24K1 DUPLOM.

DS5-SA2/10N-D12K1 DUPLOM.

DS5-SA2/11N A00 SENZA BOBINE

DS5-SA2/11N A00 SENZA BOBINE

DS5-SA2/11N-D12K1 DUPLOM.

DS5-SA2/11N-D12K1 DUPLOM.

DS5-SA2/12N-D00 SENZA BOB. C .C.

DS5-SA2/12N-D00 SENZA BOB. C .C.

DS5-SA2/12N-D24K1 DUPLOM.

DS5-SB1/10N-D00 SENZA BOB.CC

DS5-SB1/10N-D00 SENZA BOB.CC

DS5-SB1/11N-A00 SENZA BOB.CA

DS5-SB1/11N-A00 SENZA BOB.CA

DS5-SB1/11N-A110K1 C.A.

DS5-SB1/11N-D24K1 DUPLOM.

DS5-SB1/11N-D24K1 DUPLOM.

DS5-SB1/12N-D00 SENZA BOB.CC

DS5-SB1/12N-D00 SENZA BOB.CC

DS5-SB1/12N-D24K1 DUPLOM.

DS5-SB2/11N-D00 SENZA BOB.CC

DS5-SB2/11N-D00 SENZA BOB.CC

DS5-SB2/11N-D24K1 DUPLOM.

DS5-SB2/11N-D24K1 DUPLOM.

DS5-SB3/12N-D00 SENZA BOB.CC

DS5-SB3/12N-D00 SENZA BOB.CC

DS5-SB3/12N-D24K1 DUPLOM.

DS5-TA/10N-A00 SENZA BOB.C.A

DS5-TA/10N-A00 SENZA BOB.C.A

DS5-TA/10N-A110-50K1 DUPLOM.

DS5-TA/10N-A230-50K1 DUPLOM.

DS5-TA/10N-A24-50K1 DUPLOM.

DS5-TA/10N-D00 SENZA BOB.C.C

DS5-TA/10N-D12K1 DUPLOM.

DS5-TA/10N-D24K1 DUPLOM.

DS5-TA/10N-D24K1/F08 DUPLOM.

DS5-TA/11N-A00 SENZA BOB.C.A

DS5-TA/11N-D00 SENZA BOB.C.C

DS5-TA/11N-D00 SENZA BOB.C.C

DS5-TA/11N-D24K1

DS5-TA02/11N-D12K1Vii. Precautions for Use

1. Medium and Selection management

Strictly use compressed air that has been dried and filtered. A three-piece set (filter + pressure reducing valve + oil mist lubricator) must be installed at the air inlet to ensure that the oil content, dew point and cleanliness of the gas meet the standards. It is strictly prohibited to introduce liquid media such as hydraulic oil and water into the valve body to prevent the aging of the sealing parts.

Select the type based on the cylinder diameter (recommended ≤ 63mm), working pressure (0.1- 1.0MPa) and flow requirement. Overpressure use is strictly prohibited (> 1.2MPa May cause the valve body to rupture). If it is used in vacuum scenarios (< 0.1 MPa), a dedicated vacuum solenoid valve must be selected and cannot be directly replaced.

2. Installation and commissioning

Before installation, confirm the direction of the gas path (P for intake, A/B for working ports, R/S for exhaust ports). It is strictly forbidden to connect them in reverse (reverse connection will cause the cylinder to act in the opposite direction). When installing in a plate type, a sealing gasket should be added between the valve and the installation plate, and the tightening torque should be controlled at 8-10 N·m to prevent air leakage.

Before debugging, blow the gas line with compressed air for 3 to 5 minutes to remove iron filings and dust in the pipeline. The power-on test response time (≤15 ms is normal), manually press the emergency button to confirm that the valve core switches smoothly without jamming. Adjust the pressure reducing valve to stabilize the working pressure at 0.4-0.6 MPa.

The installation location should be far away from high-temperature heat sources (such as heaters) and strong magnetic field equipment to prevent coil aging or control signal interference. When installed outdoors, a rain cover should be added to ensure that the protection level remains at IP65.

3. Operation and Maintenance

During operation, check the valve body for air leakage once a week (apply soapy water to the interface; no bubbles are normal), coil temperature (normal ≤50℃, maximum ≤60℃), and exhaust noise. In case of air leakage, response delay or coil overheating, stop the machine immediately for inspection, with a focus on checking the wear of the seals or the filtration condition of the air source.

Regular maintenance every six months: Disassemble the valve body, clean impurities from the valve core and valve cavity; Check the wear condition of the sealing lip (replace it when it is aged or damaged); Apply silicon-based grease to the manual button and reset spring, and test the airtightness after reassembly.

It is strictly prohibited to keep the power on for a long time without ventilation (more than 1 hour may cause the coil to burn out). It is strictly prohibited to strike the valve body or valve core with hard objects (as it may cause deformation and jamming of the valve core). Before the equipment is shut down, the gas source should be cut off to release the residual pressure in the valve body, and then the power supply should be disconnected.

4. Storage protection

When stored for a long time, all interfaces should be sealed with dedicated plugs, and the coil terminal blocks should be sealed with insulating caps. Store in a dry warehouse with a temperature ranging from 0 to 40℃ and a humidity of no more than 60%. Avoid direct sunlight, heavy object compression and corrosive gas erosion. Power on and test the coil performance once every three months.

Before putting the valve into use after being idle for more than six months, thoroughly clean the valve cavity and replace the aged sealing parts. Low-pressure air (0.2 MPa) is introduced to test the flexibility of the valve core’s operation, and power is applied to check the response performance. Only after meeting the standards can it be connected to the system for use.

Company Profile

Frequently Asked Questions

1.What ls our Main Products?

1.Hydraulic pump

2.Hydraulic valve

3.Hydraulic motor

4.Hydraulic cylinder

5.Hydraulic parts

2. What about the MOQ?

3.What are your advantages?

- Adhere to quality first.

- Support customization, ODM & OEM service.

- 1-year warranty and complete after-sales support.

- Safe and fast shipping worldwide.

- 24-hour online service for your inquiries.

4.Are you a manufacturer? What’s your delivery time?

5.Which payment methods are accepted?

6.How will you deliver my goods?

7.How do you inspect and guarantee your products?

8.What about after-sales service?

9.What are your main applications?

- Hydraulic systems

- Agricultural machinery

- Construction machinery

- Automobile industry

- Local distributors and maintenance centers

10.Can I get a discount for bulk orders?

Professional Manufacturer